Investigation of Potential Benefits of Revising

Exception 1 under FLORIDA BUILDING CODE, ENERGY CONSERVATION, 101.4.7.1.1 Duct

Sealing upon Equipment Replacement

Janet McIlvaine

Florida Solar Energy Center

August 15, 2013

Definition of the Problem: Building science research findings have been incorporated extensively in the Florida Building Code for new construction. For new homes, the code requires the conditioned air distribution system to have a continuous sealed air barrier bounding conditioned air flow pathways. In the 2010 code, language was added to require contractors to seal accessible duct work in existing homes at the time of conditioning equipment replacement. (See relevant code section below.) However, Exception 1 excludes “ducts in conditioned space” which arguably includes unsealed return plenums formed by open framing, unsealed drywall or plywood, or poorly finished closets housing air handlers as long as they are in the conditioned space. This is a common air handler configuration in central Florida homes.

Unsealed return plenums are under significantly greater pressure than other leakage points in the air distribution system because of proximity to the fan. Return leakage from unconditioned spaces is likely to be at an extreme temperature and dusty. It often bypasses the filter, fouling equipment components, degrading equipment performance, eroding life span, comfort, and potentially indoor air quality.

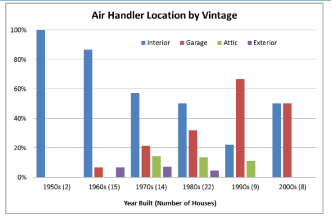

In an FSEC field study conducted between 2009-2012, researchers observed a large number of unsealed return plenums and AHU closets in the conditioned space (McIlvaine, et al.). Interior air handler configurations were found in 40 out of 70 homes ranging in vintage from the 1950’s to 2006 (Figure 1). These types of returns are often connected directly to adjacent wall cavities and attic spaces through missing or compromised air barriers.

Figure

1. Pre-retrofit air handler location in a field study of 70 central Florida

homes.

40

homes had interior AHU’s platform or whole closet return plenums.

|

|

Figure 2 (left, above) Return plenum formed by open framing under AHU support platform in an interior closet |

|

|

|

These interior air handler closets generally manifested in the field study in two configurations: a framed platform supporting an up-flow air handler with through wall filter back return grilles (Figure 2) or a metal or frame air handler stand where the closet functions as the return plenum with return air pathways through louvered doors or door mounted grilles (Figure 3).

The language added to the 2010 code presents an opportunity to address this issue unlikely to reoccur for a decade or longer. The field study referenced above showed that sealing these types of returns as part of a whole system retrofit improved duct tightness. It would be useful to assess improvement attributable to return side sealing. If improvement potential is found, it may warrant considering of a modification to make Exception 1 applicable only to supply ducts.

Approach to the research: In the field study mentioned above and more recent research, FSEC partners have achieved “substantially leak free” duct systems (Qn,out ≤ 0.03) in 20 HVAC retrofits including many with the type of returns under discussion. The portion of leakage attributable to return side pre- and post-retrofit has not been assessed because this level of investigation was not covered in the funded scope of work. FSEC’s research team proposes to leverage current U.S. Department of Energy funding by adding this line of inquiry to research planned in approximately 10 retrofits in 2013.

The technical approach, focused on platform and whole closet return plenums, would consist of duct system testing in 10 homes as follows:

• Test leakage of as found air distribution system including testing the return side alone

• Contractor will replace AC equipment and seal accessible ducts as required by code section 101.4.7.1.1 using the contractor’s standard approach

• Re-test leakage of air distribution system including testing the return side alone

• Compare pre- and post-retrofit return side leakage to characterize the relative success of the contractor’s approach and the contribution of return side improvement to overall system improvement

• Identify key elements of successful approaches.

Testing results will be used to model the impact of return sealing on heating and cooling annual energy use for several different levels of whole house efficiency representing a range of Florida housing stock.

Expected Outcome and Impact on The Code: The outcome of this research will be a report describing interior return plenum sealing practices currently in use, associated reductions in return side leakage, any risks identified and simulated projections of benefits to Florida homeowners. From the results in this report, it is expected that the Florida Building Code Commission will consider modification of Section 101.4.7.1.1 Duct sealing upon equipment replacement to capitalize on this opportunity to gradually advance the performance level of the existing Florida housing stock in terms of equipment life, energy efficiency, comfort, and indoor air quality.

Budget: $25,000

Relevant Code Reference:

2012 SUPPLEMENT TO THE FLORIDA BUILDING CODE, ENERGY CONSERVATION,

Chapter 1 – Administration, 101.4.7.1 Replacement HVAC equipment

101.4.7.1.1 Duct sealing upon equipment replacement (Mandatory). At the time of the total replacement of HVAC evaporators and condensing units for residential buildings, all accessible (a minimum of 30 inches clearance) joints and seams in the air distribution system shall be inspected and sealed where needed using reinforced mastic or code approved equivalent and shall include a signed certification by the contractor that is attached to the air handler unit stipulating that this work has been accomplished.

Exceptions:

1. Ducts in conditioned space.

2. Joints or seams that are already sealed with fabric and mastic.

3. If system is tested and repaired as necessary.